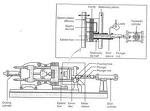

Casting is making components in a way pour the melted material into the mold. Material herein may the form of metal and non-metal. To melt the ingredients necessary furnace (cupola kitchen). Furnace is a kitchen or a place equipped with a heater (heating). The solid material melted until temperature melting point and can be added to the mixture of materials such as chrome, silicon, titanium, aluminum and other materials in order to become more good. Materials that are liquid can be poured into molds. Molds for casting can be made with sand or

metal. For components that are complex and numerous usually use sand mold, while the components that form simple and can use any mass-produced metal molds. In making molds that need to be considered is the porosity and tolerance for sringkage (depreciation) after casting. porosity the higher the better mold to release the gases trapped inside the mold.

for STEP BY STEP GUIDE solidwork simple tutorial please visit.........

www.solidworksimpletutorial.blogspot.com

---or---

Thank you for sharing superb information. Your web site is very cool. I am impressed by the details that you have on this blog. It reveals how nicely you perceive this subject. Bookmarked this web page, will come back for extra articles. You, my friend, ROCK! I found simply the info I already searched all over the place and simply couldn’t come across. What an ideal site. casting metal

ReplyDeleteSmall bits of content which are explained in details, helps me understand the topic, thank you!

ReplyDeleteMetal castings