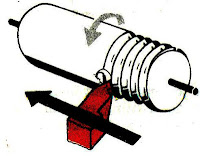

In a thread cutting operation the first step is to remove the excess material from the work piece to make its diameter equal to the major diameter of the screw thread. Change gears of correct size are then fitted to the end of the bed between the spindle and the lead screw. The shape or form of the thread depend s on the shape of the cutting tool to be used. In a metric thread, the included angle of the cutting edge should be ground exactly 60o. The top of the tool nose should be set at the same height as the centre of the work piece. A thread tool gauge is usually used against the turned surface to check the cutting tool so that each face of the tool may be equally inclined to the center line of the work piece.

The speed of the spindle is reduced by one half to one-fourth of the speed required for turning according to the type of the material being machined, and the half-nut is then engaged. The depth of cut which usually varies from 0.05 to 0.2 mm is applied by advancing the tool perpendicular at to the axis of the work or at an angle equal to one-half of the angle of the thread, and 30o in the case of metric thread, by swiveling the compound rest.

fr. NTTF ( NETTUR TECHNICAL TRAINING FOUNDATION)

1 comments:

Hello There. I found your blog using msn. This is an extremely well written article. I’ll make sure to bookmark it and return to read.

product design consultant

Post a Comment