According to the difficulties which have just been presented, the design problem often results in trial and error. It is both time and money consuming, as the shapes of the dies are complex, difficult, and expensive to produce. In order to lower these costs, several simulation strategies have been developed to replace the actual trials. Easy to form model materials such as lead, plasticine [52], and wax [64] can be substituted to the current metal, making it possible to reduce the forming force. These materials, and more particularly plasticine and wax which are more widely used today, exhibit nearly the same behavior as the metal under hot isothermal conditions. One of the main restriction of this approach is the temperature dependency of the model materials, which is quite different from the behavior of the metal.

However, for most of the processes, the forging is so fast that the heat exchanges with the dies is small and that the heat generated by the material deformation is not enough to significantly modify the material flow. Thus, this technique provides an easy way to study the material flow, to predict the major defects such as folds [42] and insufficient pressure in the die details, and to estimate the forging force. Moreover, it is possible to study the material deformation and the fibering by mixing model materials of several colors. With some mechanical models, the total strain can be computed out of these pieces of information [52]. By mixing model materials with different properties, or by adding some other components, the behavior of the model material can be slightly adjusted to the behavior of the studied metal. As often for metal forming processes, the friction phenomenon is difficult to simulate. However, some kind of model materials for the lubricants can be proposed.

The main shortcoming of this simulation approach is that although the dies can be produced into a less expensive material and without heat treatment, they are as complex as the actual process, which requires significant time and energy to produce them. Moreover, as has been mentioned earlier, the thermal effects cannot be taken into account.

Nowadays, the numerical simulation provides much faster results as the toolings are only virtually designed. Moreover, these results are more accurate and more varied, such as the flow at different times of the process, the velocity field, the strain, the strain rates, the stresses, the temperature, the tool wear, and the tool deformation. Several softwares have been marketed, such as the well spread FORGE2 and DEFORM2D (initially called ALPID), [47] for axisymmetrical and plane strain problems.

They are actual tools for designers and their industrial use is ever increasing. Indeed, they make it easy to quickly find the main shortcomings of the studied design, and then to test several modifications to improve it. For expensive safety parts, or for very large single parts, they also provide a quality insurance as they give an estimation of the mechanical characteristics of the part which should otherwise be obtained by destructive testing. Regarding the true three-dimensional problems, automatic remeshing difficulties, as well as computational time and memory requirements, have long hindered the industrial use of these softwares.

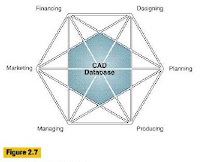

Nowadays, both the software and hardware progresses have made these computations possible. They are used in forging companies, for instance to understand the development of a fold and test whether a new preform design can remove it [22]. The tool shape discretization required for the numerical simulation, often a finite element mesh of the tool surface by triangles, can almost directly be obtained from the CAD design. It reduces to rather insignificant times the specific numerical design required by the finite element simulation. FORGE3 and DEFORM3D [66] are such available softwares

COMPUTER-AIDED DESIGN,

ENGINEERING, AND MANUFACTURING

Systems Techniques And Applications

VOLUME V I

Editor

CORNELIUS LEONDES

Boca Raton London New York Washington, D.C.

CRC Press

MANUFACTURING

SYSTEMS PROCESSES