A drawing should provide a complete specification of the component to ensure that the design intent can be met at all stages of manufacture. Dimensions specifying features of size, position, location, geometric control and surface texture must be defined and appear on the drawing once only. It should not be necessary for the craftsman either to scale the drawing or to deduce dimensions by the subtraction or addition of other dimensions. Double dimensioning is also not acceptable.

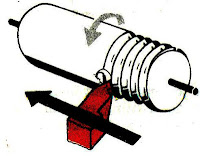

Theoretically any component can be analysed and divided into a number of standard common geometrical shapes such as cubes, prisms, cylinders, parts of cones, etc. The circular hole in Fig. 14.1 can be considered as a cylinder through the plate. Dimensioning a component is the means of specifying the design intent in the manufacture and verification of the finished part.

A solid block with a circular hole in it is shown in Fig. 14.1 and to establish the exact shape of the item we require to know the dimensions which govern its length, height and thickness, also the diameter and depth of the hole and its position in relation to the surface of the block. The axis of the hole is shown at the intersection of two centre lines positioned from the left hand side and the bottom of the block and these two surfaces have been taken as datums. The length and height have also been measured from these surfaces separately and this is a very important point as errors may become cumulative and this is discussed later in the chapter.

Dimensioning therefore, should be undertaken with a view to defining the shape or form and overall size

of the component carefully, also the sizes and positions of the various features, such as holes, counterbores,

tappings, etc., from the necessary datum planes or axes.

The completed engineering drawing should also include sufficient information for the manufacture of the part and this involves the addition of notes regarding the materials used, tolerances of size, limits and fits, surface finishes, the number of parts required and any further comments which result from a consideration of the use to which the completed component will be put. For example, the part could be used in sub-assembly

and notes would then make reference to associated drawings or general assemblies.

British Standard 8888 covers all the ISO rules applicable to dimensioning and, if these are adhered to, it is reasonably easy to produce a drawing to a good professional standard.

1 Dimension and projection lines are narrow continuous lines 0.35 mm thick, if possible, clearly placed outside the outline of the drawing. As previously mentioned, the drawing outline is depicted with wide lines of 0.7 mm thick. The drawing outline will then be clearly defined and in contrast with the dimensioning system.

2 The projection lines should not touch the drawing but a small gap should be left, about 2 to 3 mm, depending on the size of the drawing. The projection lines should then continue for the same distance past the dimension line.

3 Arrowheads should be approximately triangular, must be of uniform size and shape and in every case touch the dimension line to which they refer. Arrowheads drawn manually should be filled in. Arrowheads drawn by machine need not be filled in.

4 Bearing in mind the size of the actual dimensions and the fact that there may be two numbers together

where limits of size are quoted, then adequate space must be left between rows of dimensions and a

spacing of about 12 mm is recommended.

5 Centre lines must never be used as dimension lines but must be left clear and distinct. They can be extended, however, when used in the role of projection lines.

6 Dimensions are quoted in millimetres to the minimum number of significant figures. For example, 19 and not 19.0. In the case of a decimal dimension, always use a nought before the decimal marker, which might not be noticed on a drawing print that has poor line definition. We write 0,4 and not .4. It should be stated here that on metric drawings the decimal marker is a comma positioned on the base line between the figures, for example, 5,2 but never 5·2 with a decimal point midway.

7 To enable dimensions to be read clearly, figures are placed so that they can be read from the bottom of the drawing, or by turning the drawing in a clockwise direction, so that they can be read from the right hand side.

8 Leader lines are used to indicate where specific indications apply. The leader line to the hole is directed towards the centre point but terminates at the circumference in an arrow. A leader line for a part number terminates in a dot within the outline of the component. The gauge plate here is assumed to be part number six of a set of inspection gauges.

READ MORE.......

Manual of

Engineering Drawing

Second edition

Colin H Simmons

I.Eng, FIED, Mem ASME.

Engineering Standards Consultant

Member of BS. & ISO Committees dealing with

Technical Product Documentation specifications

Formerly Standards Engineer, Lucas CAV.

Dennis E Maguire

CEng. MIMechE, Mem ASME, R.Eng.Des, MIED

Design Consultant

Formerly Senior Lecturer, Mechanical and

Production Engineering Department, Southall College

of Technology

City & Guilds International Chief Examiner in

Engineering Drawing